The TRIUMF 4-channel Equipment is designed to testing Common Rail injectors manufactured by Bosch, Delphi, Denso, VDO Siemens, Cummins, AZPI, as well as HEUI Caterpillar unit injectors. The Equipment allows you to simultaneously check 4 injectors, as well as control the temperature of the test liquid on each injector.

The software allows coding BOSCH isa / ima cod, Delphi C2i / C3i / C4i*, Denso, VDO Siemens injectors.

Stand working pressure up to 2400 bar. The functions of creating new test plans, editing built-in ones, as well as creating targets for Delphi C2i, C3i, C4i injectors are available. The results and progress of testing are displayed in graphical form and saved to a file and sent to print.

The stand is produced with the following characteristics of the main drive:

- TRIUMF 4 kW 380 V,

- TRIUMF 5.5kW 380V

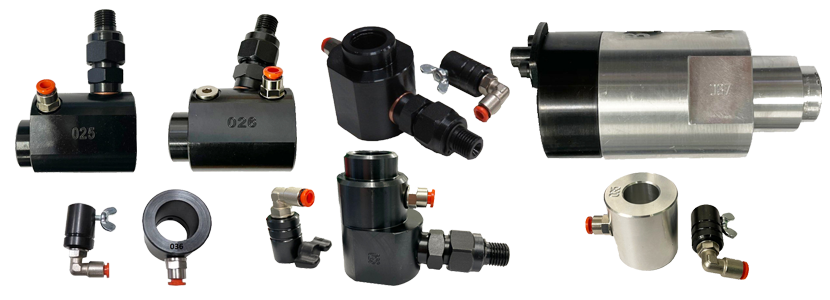

For coding Delphi injectors, inside stand installed device that allows you to create a vacuum in the injector backflow line. The set of the vacuum device includes a gear pump, a venturi tube and an electric motor. The device is installed on a partition, which is located in the lower part of the stand above the refrigeration unit. Also in the working (testing) area at the top right there is a pressure gauge measuring vacuum with an electrovalve providing vacuum access to the injector. In this case, the vacuum is regulated by a throttle grip installed under the monitor on the left. When coding Delphi injectors in the TRIUMF Equipment, a sensor is used that determines the injection start time.

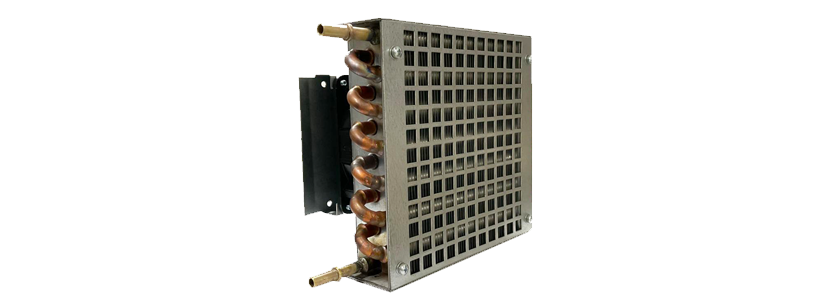

For thermal stabilization of the test liquid in the tank, the following are used:

- two radiators with forced air cooling for the backflow line from the injection pump and the backflow line from the pressure accumulator (rail).

- independent refrigeration unit with air heat exchanger.

- tubular electric heater with a power of 1000 W.

The Equipment has an electronic measurement system with the ability to simultaneously check 4 injectors.

Software with test plans is included in the package. The program has a user-friendly interface in Russian and English, updates includes new test plans, released twice a year and provided freely.